organic residues to advanced nutrients.

Our solutions recover nutrients that would otherwise be lost, protect the environment and conserve valuable resources. We offer sustainable high-performance fertiliser products for sustainable agriculture.

- TECHNOLOGIES

- CONDITIONING

- CONVERSION

- FRACTIONATION

- MIXING

Technologies for recycling chains that make economic sense

Recovering nutrients from materials like sewage sludge, fermentation products, slurry or biowaste hasn’t made financial sense until now due to a lack of cohesive technology chains.

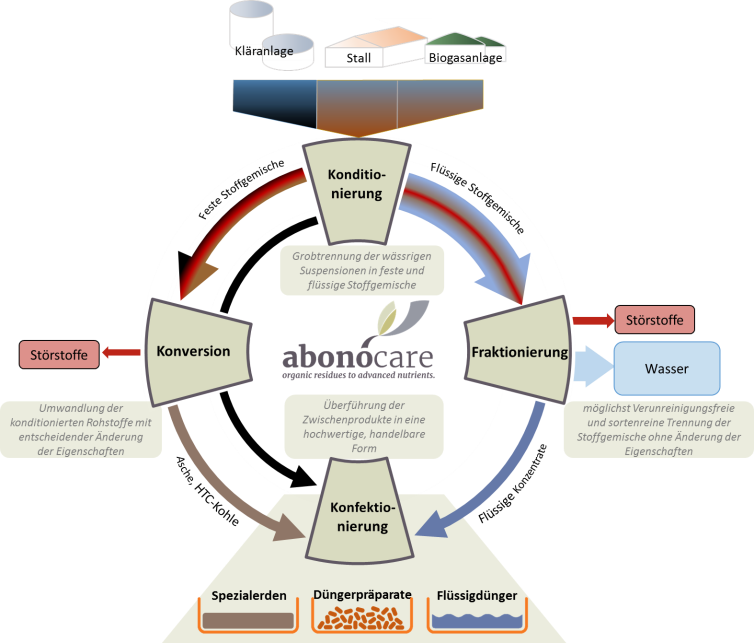

abonocare® provides economically viable value chains for recovering nutrients from organic waste. Our innovative technologies for conditioning, converting, fractionating and mixing organic waste facilitate joined-up technology, material and value chains which can produce a range of fertiliser products from input materials.

From a technology perspective, abonocare® focuses on new units, processes and excipients for solid-liquid separation, specific membrane separation and extraction methods to improve stripping, precipitation and crystallisation processes, biomass conversion processes with simultaneous contaminant reduction and innovative granulation, coating and homogenisation processes for novel and functional fertiliser products which involve modifying chemical processes.

In the mixing stage of the abonocare® technology chain, concentrates are combined with other components to create specialised fertiliser products that are tailored to customer requirements. This stage ensures that the product meets the needs of the end customer in terms of uptake, stability, homogeneity and abrasion resistance so that it is suitable for sale.

Contact

Matthias Hoger

Telephone +49 (0) 34205 / 738 - 19

Mobile +49 (0) 163 / 738 00 11

info@abonocare.de

A multi-feedstock system for economically viable nutrient recovery

Conditioning is the first stage in the processing of organic waste like sewage sludge, fermentation products and slurry to create fertiliser products. These materials tend to have a high liquid content at the beginning of the process. Conditioning dries them out to make them easier to process and handle. Equipment like centrifuges, screw separators, vibrating screens or presses is normally used for this purpose, but tends not to do an effective job.

abonocare® provides multi-feedstock conditioning technologies which make it possible to prepare organic waste for targeted nutrient recovery in situ or at a central location. This reduces volumes, increases the proportion of solid material in intermediate products and provides an end product that is far more stable than what was previously possible.

abonocare® uses high-performance separation units with electromagnetic systems and polyacrylamide-free flocculating agents for an efficient solid-liquid separation process. We also use compact, energy-efficient steam dryers with an integrated nitrogen separation system. These are just two examples of the wide range of technology we have available in this field. Having so many options at our disposal means that we can provide a tailored solution for your secondary raw materials. Get in touch to see what we’re capable of!

Contact

Matthias Hoger

Telephone +49 (0) 34205 / 738 - 19

Mobile +49 (0) 163 / 738 00 11

info@abonocare.de

Conversion for refining biomass

A number of different systems are currently used to burn solid biomass for the purpose of generating heat and/or electricity. The biomass usually has to be prepared first. The conversion process provides suitable secondary energy sources in liquid and gaseous form with a higher energy density and stability. Conversion can also make biomass suitable for use as an energy source with existing technology in a similar set-up to the existing energy system.

abonocare® provides a wide range of technologies for combusting organic secondary raw materials and ash modification.

One of abonocare® ’s core competencies is the hydrothermal process. This process can refine a wide range of wet biogenic materials into solid, liquid or gaseous sources of carbon. The process is just as suitable for slurry and digestate as it is for sewage sludge, municipal biowaste or cuttings from road verges.

The end product of the hydrothermal carbonisation (HTC) process is a char product - a climate-neutral fuel with a high degree of energy efficiency. HTC is a particularly economical alternative to composting, biochemical conversion or direct thermal utilisation for waste flows containing water. We consider HTC to be a refinement stage in the process of creating new products from biogenic waste in the context of a circular economy.

The conversion and fractionation stages provide solid and liquid nutrient products, in addition to materials which provide structure (digestate, hydrochar) at concentrations and with granulometric and rheological properties that are tailored to specific applications and customer requirements. These products can then be processed to create market-ready specialised fertilisers and additives for gardening soil for conventional and organic agriculture. Get in touch to see what we’re capable of!

Contact

Matthias Hoger

Telephone +49 (0) 34205 / 738 - 19

Mobile +49 (0) 163 / 738 00 11

info@abonocare.de

Tailored products that are easy to use

abonocare® focuses on recovering nutrient fractions from liquid organic waste (e.g. fermentation products from nutrient-rich solid poultry manure, food waste, low viscosity slurry) and process waters (HTC waste water with low levels of contaminants).

abonocare® has a wide range of methods and technologies at its disposal to suit different nutrient separation processes and different substances, such as stripping, membrane separation, membrane extraction, precipitation and crystallisation.

abonocare® uses a variety of integrated and down-stream technologies to create high-value products which can be processed for different applications. These include ammonium sulphate liquor (ASL), lime through the use of gypsum (conditioned to create specialised fertilisers), ASL using a membrane contactor and acid process, pure ammonium carbonate salts with no additives, magnesium ammonium phosphate (MAP) with no magnesium chloride and highly concentrated liquid potassium fertiliser.

Contact

Matthias Hoger

Telephone +49 (0) 34205 / 738 - 19

Mobile +49 (0) 163 / 738 00 11

info@abonocare.de

Mixing for different applications

abonocare® provides the processes, systems and technological solutions needed for the economical, eco-friendly, flexible and uncomplicated production of granular fertilisers and specialised soils from secondary raw materials containing phosphorous and mixing them with other secondary nutrient components.

abonocare®’s granulation, coating and homogenisation technology and innovative modification of chemical processes make it possible to combine mineral crystalline, liquid and organic materials to optimise mechanical and chemical stability and maximise nutrient uptake.

Here’s a real-world example: We use the SERAPLANT process to convert waste containing phosphate into a product with excellent phosphate uptake that is already economically viable in the current market environment. Secondary raw materials containing phosphate are treated with a mineral acid before nutrient components are added. The blend is then spray granulated. This process makes it possible to combine different secondary raw materials containing phosphate to create different fertiliser products. This process gives us the flexibility we need to respond quickly to changes in the market.

Contact

Matthias Hoger

Telephone +49 (0) 34205 / 738 - 19

Mobile +49 (0) 163 / 738 00 11

info@abonocare.de